1.8mm copper rod

Unparalleled conductivity for your projects

Need a highly conductive material for your next project? Our 1.8mm copper rods offer exceptional conductivity and malleability, perfect for a wide range of applications. Whether you’re building electrical circuits, heat sinks, or crafting jewelry, our copper rods provide the reliability and performance you need. With excellent corrosion resistance and easy workability, our copper rods are a versatile choice for any project. Contact us today to learn more about our copper wire and place your order. kayhanmetal

Advantages of 1.8 mm wire

- High electrical and thermal

- conductivity

- Corrosion resistance

- Excellent malleability

- Wide application in various

- industries

Applications of 1.8 mm copper rod

- Electrical Conductivity

- Heat Sinks

- Electromagnets

- Welding

- Jewelry Making

- Laboratory Equipment

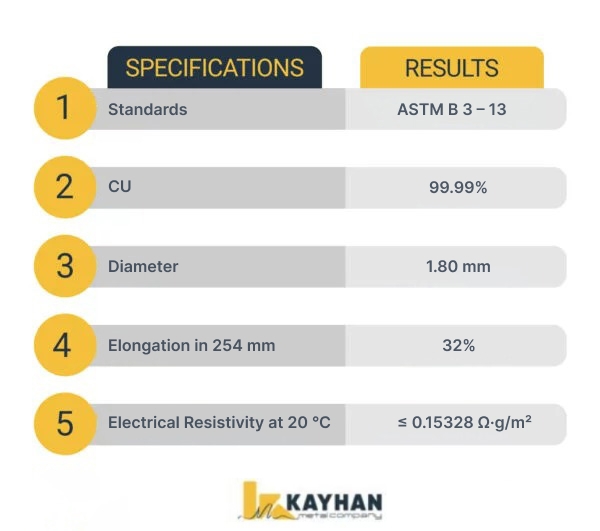

Technical specification table

Standards & Specifications : ASTM B3-13

Size availability :1. 8 mm

1.8 mm copper wire rod typically involves the following processes:

1. Continuous Casting and Rolling

This is the most common method for producing copper wires of standard diameters:

Continuous Casting:

- Electrolytic copper cathodes are melted in specialized furnaces.

- The molten copper is continuously poured into cooled molds to form thick rods (billets).

Hot Rolling:

- The cast billets are passed through several rolling stages to reduce their diameter to around 8 mm.

Cold Drawing:

- The 8 mm rod is further drawn through wire-drawing machines with successive dies to achieve the desired diameter of 1.8 mm.

- This process ensures high precision and uniformity in diameter.

2. Extrusion

In some cases, extrusion is also used for producing copper wires:

- Copper is melted and poured into extrusion molds.

- High pressure pushes the material through a die to achieve a specific diameter.

- The extruded wire is cooled and further drawn to 1.8 mm if necessary.

3. Annealing Process

After drawing the wire to 1.8 mm, it may undergo annealed copper:

- This heat treatment increases the wire’s flexibility.

- It also enhances its mechanical and electrical properties.

Benefits of Continuous Casting and Rolling:

- High-quality output.

- Faster production rates.

- Lower manufacturing costs.

FAQs

A 1.8mm copper rod is a cylindrical piece of copper with a diameter of 1.8 millimeters. Copper is a highly conductive metal, making these rods ideal for various applications in electronics, jewelry making, and more.

- Electronics: Used in printed circuit boards, connectors, and wiring.

- Jewelry making: Used for creating various jewelry pieces.

- Heat sinks: Used to dissipate heat from electronic components.

- DIY projects: Used for various hobby and craft projects.

Yes, copper is a malleable metal and can be easily bent. However, for tighter bends, annealing may be required.

The tensile strength of a 1.8mm copper rod can vary depending on the specific alloy and temper. However, a typical value for annealed copper wire of this size is around 45 MPa (megapascals).

It’s important to note that the tensile strength can be affected by factors such as the manufacturing process, impurities in the copper, and the specific application. If you need a more precise value for your specific use case, it’s recommended to consult the product specifications from the manufacturer or supplier.