2.6 mm copper rod

Unparalleled conductivity for your projects

Looking for a versatile and reliable conductor? Our 2.6mm copper rods are your go-to choice. With exceptional conductivity and malleability, these rods are perfect for a wide range of applications, from electrical wiring and heat sinks to jewelry making. Their corrosion resistance and easy workability make them a popular choice for both DIY enthusiasts and professionals. Kayhanmetal is known as a copper wire distribution and supplier company.

Advantages of 2.6 mm copper rod

- Excellent Conductivity

- Durability and Longevity

- Malleability and Formability

- Versatility

- Cost-Effective

- Recyclability

Applications of 2.6 mm copper rod

- Electrical Conductivity

- Heat Sinks

- Electromagnets

- Welding

- Jewelry Making

- Laboratory Equipment

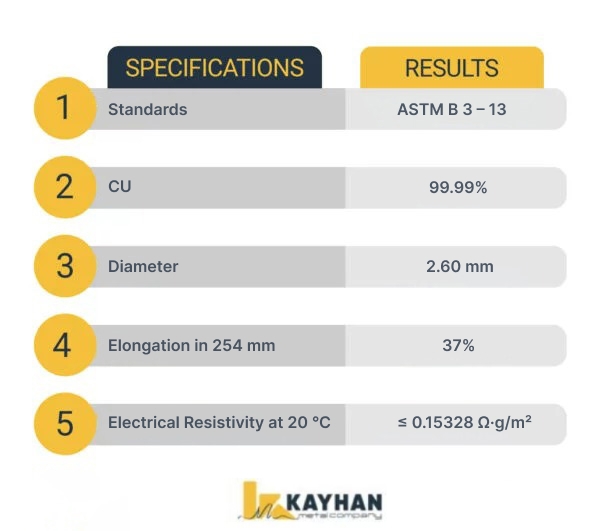

Technical specification table

FAQs

A 2.6mm copper rod is a solid, cylindrical piece of copper that has a diameter of 2.6 millimeters. Copper is a metal known for its excellent electrical conductivity and thermal conductivity. These rods are commonly used in various applications due to their properties.

2.6mm copper rods find extensive use in a variety of applications due to their exceptional electrical and thermal conductivity, as well as their malleability. Common uses include electrical wiring, where they provide efficient current flow; heat sinks, where they dissipate heat from electronic components; and electromagnets, which rely on copper’s magnetic properties. Additionally, 2.6mm copper rods are employed in welding, jewelry making, and laboratory equipment, showcasing their versatility across diverse industries.

A 2.6mm copper rod is quite thin and can be easily bent by hand. However, the exact ease of bending will depend on the specific alloy of copper used, as some alloys are harder than others. If you need a very precise bend, you might consider using a pair of pliers or a bending jig. Remember, the smaller the bend radius, the more force required. Always ensure you’re wearing appropriate safety gear when working with metal.

The tensile strength of a 2.6mm copper rod can vary significantly based on several factors including the specific copper alloy, the manufacturing process, the rod’s temper (annealed, half-hard, or full-hard), and the presence of impurities. Copper alloys, such as brass or bronze, can have different tensile strengths compared to pure copper. Additionally, the method of manufacturing, such as cold drawing or hot rolling, can influence the final strength. To obtain an accurate value for the tensile strength of a 2.6mm copper rod, it is recommended to consult the specific material datasheet provided by the manufacturer or conduct a tensile test on the exact rod in question