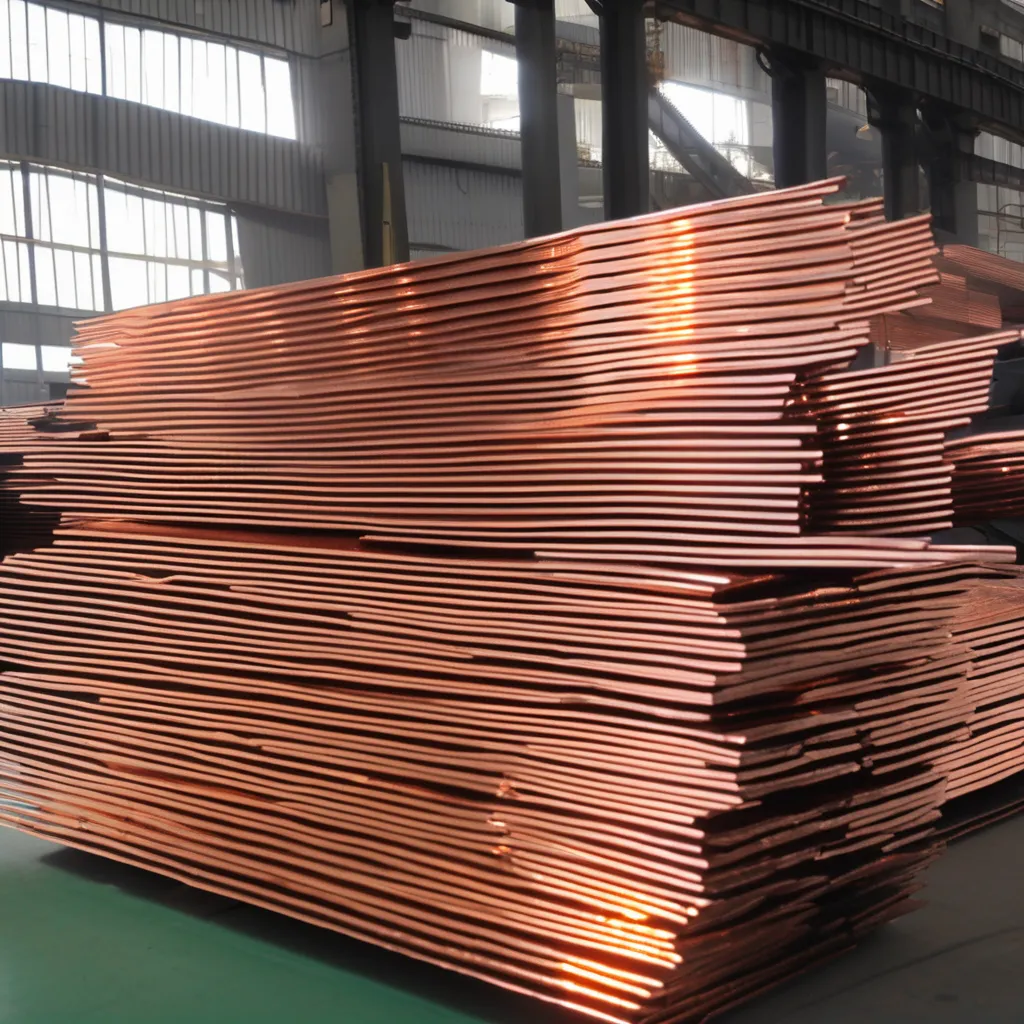

Premium Copper Cathodes for High-Quality Metal Production

Our Copper Cathodes Offer Unmatched Purity and Performance for Your Industrial Needs. With a purity of over 99.99%, our copper cathodes are the ideal raw material for manufacturing high-quality copper wire & rods. Whether you’re in the electronics, construction, or automotive industry, our copper products ensure superior conductivity, durability, and long-lasting performance. By choosing our copper cathodes, you are investing in a product that sets the standard for excellence and reliability in metal production

What is Copper Cathode?

Copper cathode is a high-purity form of copper that is produced through the electrolysis of copper ore or copper scrap. It is the final product obtained from the refining process, where impurities are removed from the raw copper. With a purity of over 99.99%, copper cathodes serve as the primary raw material for producing various copper products such as copper wire, copper rods, and sheets. These cathodes are crucial in industries like electronics, construction, and manufacturing due to their excellent conductivity and durability.

Why Choose Our Copper Cathodes?

| Feature | Description |

|---|---|

| High Purity | Over 99.99% purity, ensuring the production of high-quality products. |

| Consistent Quality | Our copper cathodes are reliable with consistent quality in every batch. |

| Corrosion Resistance | Resistant to corrosion and wear, making them ideal for harsh industrial environments. |

| High Conductivity | High-purity copper enhances conductivity, improving performance in electrical and electronic applications. |

| Versatile Applications | Ideal for manufacturing copper wire and copper rods, as well as for use in automotive and electronics industries. |

| Global Shipping | Fast and reliable shipping worldwide. |

| 24/7 Customer Support | Round-the-clock support to ensure customer satisfaction. |

Copper Cathode Production Process

A [Copper Ore Extraction] –> B[Crushing and Grinding];

B [Crushing and Grinding] –> C[Concentration];

C [Concentration] –> D [Smelting];

D [Smelting] –> E [Electrorefining];

E [Electrorefining] –> F [Copper Cathode Production];

F [Copper Cathode Production] –> G [Final Inspection & Packaging];

Step-by-Step Process:

- Copper Ore Extraction: Copper is extracted from mines.

- Crushing and Grinding: The copper ore is crushed and ground to prepare it for the next stages.

- Concentration: In this stage, copper is separated from impurities and becomes more concentrated.

- Smelting: The copper is melted in a furnace to separate it from other materials.

- Electrorefining: The molten copper is placed in an electrolyte solution, where pure copper deposits onto the cathode.

- Copper Cathode Production: Copper cathodes with 99.99% purity are produced.

- Final Inspection & Packaging: Finally, the copper cathodes are inspected and packaged for shipment to the market.

What are the uses of copper cathodes?

Copper cathodes are primarily used to manufacture copper products such as copper wire, copper rods, and copper sheets. These products are essential for a variety of industries, including electrical and electronics manufacturing, construction, automotive, and telecommunications. Copper cathodes are valued for their high conductivity, resistance to corrosion, and ability to be easily shaped into different products for industrial applications.

What is the difference between copper cathodes and copper scrap?

Copper cathodes are the purest form of copper, typically containing over 99.99% copper content. They are produced through the electrorefining process, starting with copper ore. On the other hand, copper scrap refers to used or waste copper material, such as old wires, pipes, and electrical components, which can be recycled. Copper scrap is often processed to extract copper through melting and refining, but it is typically not as pure as copper cathodes. Copper cathodes are preferred for manufacturing high-quality products due to their superior purity and consistency.